Gary Coates

Over 23 years in the stainless steel industry, both at the mill and service centre level, then 10 years in an industry trade association as Technical Director. Independent consultant since 2009. Experience in Europe, North America, and Asia. Works with recognized metallurgical consultants worldwide. Member of PEO, NACE, ASM, CIM, SME

Get in touch

Training

Xian welcoming sign training. Gary being welcomed to Xi`an China to deliver a half day course on stainless steels for the food and beverage industry at a local university. Gary provides custom-tailored training courses for many industries and at all levels.

Expertise

Gary has expertise in the welding of stainless steel and nickel alloys of all types. He has worked for many years with the various types of duplex and specialty austenitic stainless steels.

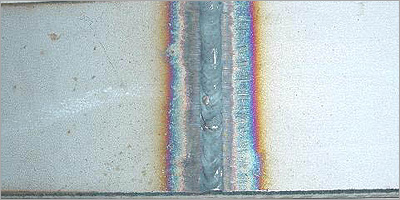

Heat tint

Heat tint left on stainless steel welds are places where pitting corrosion can initiate. The proper cleaning of welds is a very important step in the fabrication process.

Corrosion

Crevice corrosion often occurs underneath gaskets on stainless steel flanges. Gary helps industry to solve all kinds of corrosion problems.